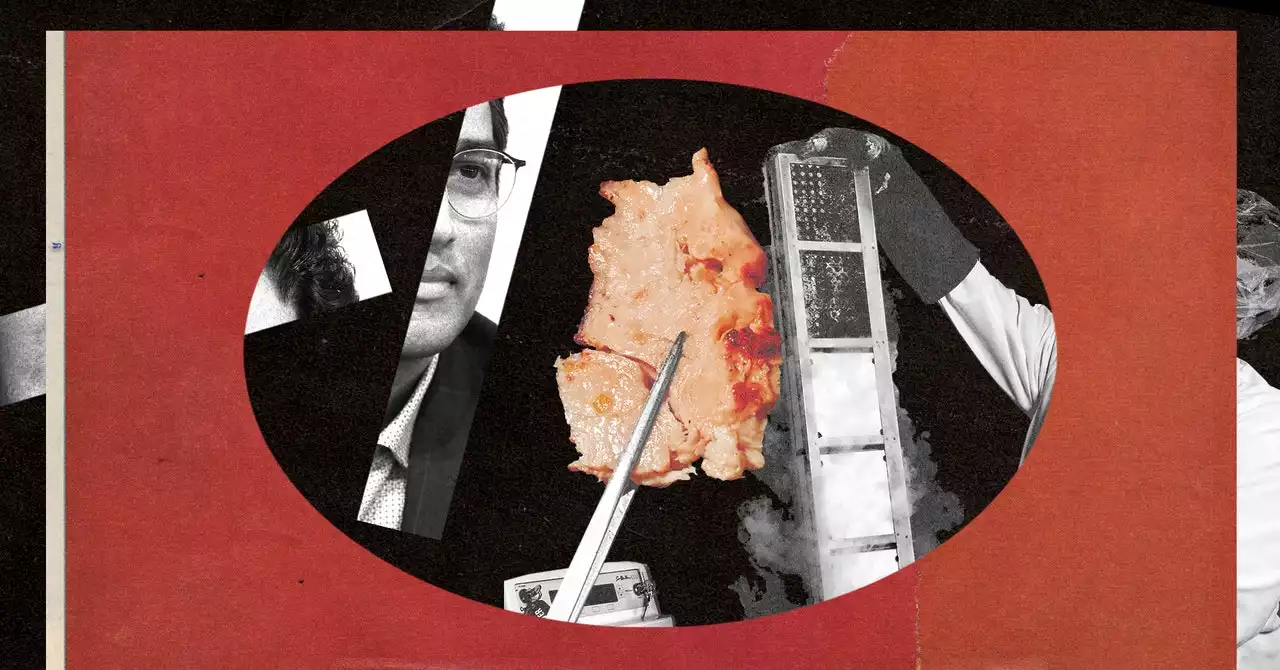

Billion-dollar cultivated-meat startup Upside Foods wants you to think the breakthrough chicken fillets it sells are made in a futuristic factory. A WIRED investigation tells a different story.

But roller bottles aren’t just problematic due to their miniscule output. They’re also expensive and wasteful, according to numerous biopharma and cultivated-meat industry sources. Each flask is made from sterile, single-use plastic, which must be discarded or recycled once it has generated its 2 to 3 grams of tissue. Given that an ordinary 2-liter plastic drink bottle, Upside’s current production method likely produces plastic waste more than 10 times faster than it makes meat.

There are two distinct goals in scaling up, Humbird says: increasing the volume of what you make and how efficiently you make it. He argues that roller bottles fail in both respects—and that diners eating Upside’s chicken at a restaurant should be made aware of the “thousands of dollars of labor” that went into preparing the cultivated meat for each night’s meal service, regardless of what they pay at the end of the meal.

But the chicken served at Bar Crenn uses multiple animal-derived ingredients. The roller bottles in which the tissues are grown are coated with porcine gelatin to help the cells stick to the plastic surface. An FDA safety dossier submitted by Upside also confirms that it might use bovine serum to grow its cells. The current employee also said that bovine serum—derived from the blood of adult cattle—is being used in the roller bottle process for Bar Crenn.